New options for cultivations and drilling

29th December 2021

A visit to Lemken’s German Agro Farm in mid-November included news and demonstrations of significant updates and new products which will be welcomed by UK farmers. David Williams was there.

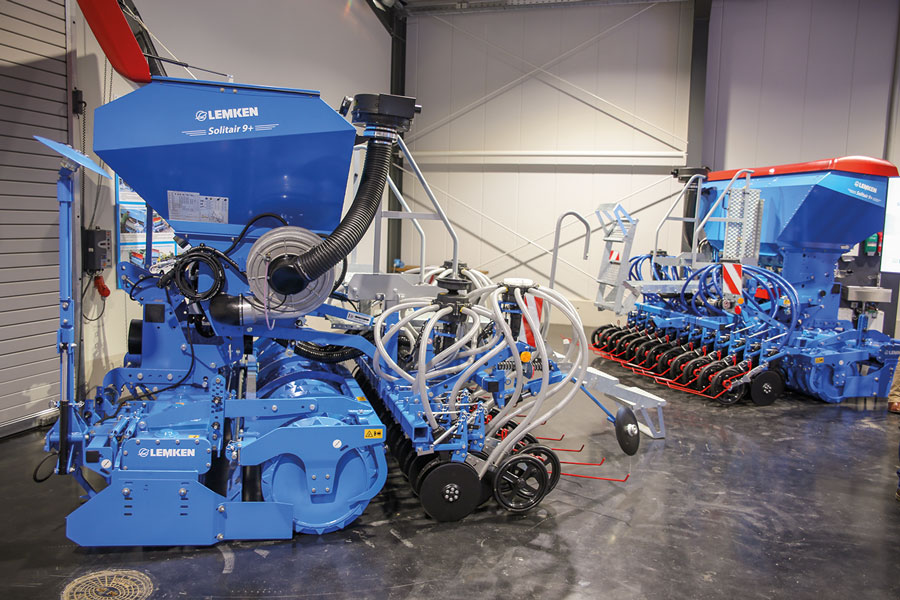

Lemken demonstrated its new Solitair DT drill at a German press event in mid-November.

Lemken started the event reporting excellent worldwide sales and stressed that there is no sign of the sales boom ending. More than 4,000 seeding machines will be sold this year, but challenges include 95% increased steel costs compared with this time last year, and electronic components costing five times as much. The company believes that decarbonisation is a fantastic opportunity for farmers, although machinery must be developed to take full advantage. It added that the role of digitalisation and intelligent solutions for the future can’t be over-estimated.

Black-grass control

Regarding black-grass control, Lemken has been involved with trials at Stow Longa in Cambridgeshire for many years, and the company’s presentation highlighted actions identified so far which can help reduce the weed burden:

Restructure soil adequately to allow later drilling – but check depth of restructuring needed, otherwise there is a tendency to work too deep with associated increased costs.

Ploughing can provide effective control, either on a rotational basis or as part of a management system – but it was stressed that a plough shouldn’t be used only because there is one on the farm.

Limiting soil cultivations close to, or at, drilling reduces black-grass populations. The more soil movement that occurs then the more black-grass will germinate.

Catch or cover crops have a role and a longer-term impact on soil structure, but proper restructuring relies on steel.

Finally – delaying crop drilling until the second half of October reduces black-grass populations by half.

Mechanical and targeted weed control

The IC-Weeder AI with artificial intelligence to recognise crops has joined Lemken’s Steketee range. Distinguishing between weeds and crop allows targeted hoeing, so weeds can be mechanically removed even where there are large weed populations in growing crops.

So far, the system has been trained to recognise sugar beet plants at various stages of development by their colour, texture, shape, size, and leaf position. This allows reliable hoeing even in challenging conditions too complex for conventional recognition systems.

The cameras are protected under a hood so that they aren’t affected by ambient light. Thirty images per second are transmitted to the on-board computer, and the sickle shaped, pneumatically controlled blades hoe the rows between the plants operating as close as 2cm and retract as each sugar beet plant is approached.

Although sugar beet is the first targeted application, other crops – including lettuce, celery and cabbages grown from seed – are likely to be added later. Where larger plants are transplanted, then the difference in plant size compared to surrounding weeds in the prepared soil means that conventional inter-row hoes without plant recognition are adequate. The cameras and plant recognition software recognise sugar beet plants with at least four true leaves at working speeds up to 3kph with 97% accuracy. Lemken stressed that the IC-Weeder AI makes hoeing effortless and precise, and it is also a significant step towards fully automated driving systems. First deliveries are due this year of 3m models costing approximately £100,000, and a 6m version will follow.

Calibration is easily carried out from the platform.

Disc coulters place fertiliser below the seed rows on the double-shot version, or supply seed and fertiliser through the same coulters on the single-shot model.

Lemken has added an inter-row hoe with artificial intelligence to identify sugar beet plants from camera images, allowing selective weeding at speeds up to 3kph.

Advanced sprayer solution

Also new in the Steketee range is the SprayHub front tank, intended to supply band spray nozzles for targeted weed control within plant rows, while mechanical hoes remove weeds between the rows. Using Lemken’s SprayKit application system with the mechanical inter-row hoes – the company suggests that 40–60% less spray chemical is needed than for full width spraying. It is also time efficient as mechanical hoeing and spraying are carried out in one pass.

The SprayHub is basically a self-contained sprayer, incorporating a hydraulic-driven pump, spray controls, and agitator and cleaning systems. With Isobus control, it can be operated through MegaSpray software. Tank capacity options are 1,100 or 1,500 litres and the tank unit comes with an integral clean water tank, hand wash canister and filling screen. An optional induction nozzle is available for dissolving solid spray agents, and a Closed Transfer System (CTS) connection is also available.

The SprayKit is also suitable for use with other implements, and not just hoeing machines, and it features mechanical section control. Single row control will be added, allowing automatic section control through GPS.

The SprayHub with SprayKit will be available from this spring, and options including adaptors for use with drop hoses and for under-root fertilisation will follow.

Solitair range increased

The new Solitair DT drill (pictured on page 151) has a lower draft requirement allowing use with smaller tractors, and it is available with a large, divided hopper for combined seeding and fertiliser applications.

The hopper holds up to 5,100 litres, and there are two variants – a single-shot version allows seed and fertiliser to be placed together in a shared sealed furrow, whereas the double-shot version places fertiliser in a band below the seed level through a leading set of double disc coulters with working pressures up to 200kg per unit to ensure accurate depth control. The individually mounted seeding coulters have direct hydraulic pressure control with up to 70kg available, ensuring even depth across the working width.

The drill is easily set up for different crops and conditions, and options include delivering fertiliser through the front disc coulters at 25cm spacing, while seed is delivered every 12.5cm, allowing fertiliser placement between the rows. Two dosing units metering different seeds from each hopper also allows supply at different rates to the rear OptiDisc coulters.

A front tyre packer reconsolidates the land and has gaps matching the tractor wheeltrack for an even finish. The packer is followed by a compact disc harrow with large 465mm concave discs which are individually mounted and protected against overload. For reduced soil disturbance, vertical waffle discs are available which penetrate less – reducing moisture loss and weed emergence. For targeted reconsolidation of the seed rows a trapeze packer roller can be attached behind the disc harrow.

The new metering units are electrically driven, and each supplies one distributor with seeds. The metering wheels are combined into seed wheel cassettes, eliminating the need to switch seed wheels on and off, and the cassettes can be changed without tools. With electric drive, GPS section control is easily achieved.

Seed placement is by proven OptiDisc double disc coulters with depth control wheels, mounted on parallelogram linkages.

Lemken suggests typical fuel consumption of only 5 litres/ha when using the new drill, while speeds of 14–16kph achieve high work rates up to 9.6ha/hr.

Hitching to the lower links allows 90-degree turns without risk of contacting the tractor tyres. Calibration is simply and conveniently carried out from the platform along-side the metering units.

Isobus control is standard and there is no need for a tractor with complex hydraulic systems as standard spools are suitable.

The Solitair 9+ is now available in single- and double-shot versions and with a split hopper, allowing fertiliser to be placed while seeding, and multiple seed types to be drilled in one pass.

Solitair 9+ – more options

The Solitair 9+ Duo (pictured above left) adds versatility over the standard Solitair 9+ launched last year. The Duo model features a split hopper for seed and fertiliser, two different types of seed, or seed and catch crops.

The hopper’s 1,850kg capacity can be divided 50/50 or 60/40.

A single-shot version combines seed and fertiliser from the metering units of both hopper segments. This is ideal for adding fertiliser while drilling winter cereal crops for rapid establishment. Automatic tramlining is integrated within the distributors.

The double-shot version provides greater flexibility as the two components flow separately to double disc coulters from doubled distributors through individual seed pipes. Both products can be placed in a single row, or separately and alternately in two rows just by swapping the tramline cartridge in the distributor. Further flexibility includes the placement depth as every other row can be set separately through the pressure rollers up to a difference of 5cm, making the drill ideal for seeding beans and mustard simultaneously for example. Different seeds can be placed at their respective optimum depths, or inter-row fertilisers can be ideally placed while seeding.

Full availability is forecast from this month in 3m and 4m versions.

The Karat 10 cultivator has a new tine layout making it easier to pull. A range of optional cultivation elements from levelling tines to star discs, and a wide selection of rear packers are available and can be easily switched.

Karat 10

With three beams and symmetrically arranged tines, the Karat 10 (above) retains the previous Karat 9’s soil mixing ability, but the new layout reduces the draft requirement and side forces.

A greater range of equipment options and drawbars suits more applications and allows use with tractors fitted with wider tyres.

For ultra-shallow cultivations wider winged shares are available, while narrow shares can be quickly fitted instead for deeper cultivations.

Specially shaped guide plates achieve improved mixing and DeltaCut shares are available for shallow cultivations.

Edge levelling tools are also new, allowing use with the cultivator folded.

Leading discs on individual leaf springs are an option to break up clods, and chop and incorporate large volumes of organic matter. Adjustable levelling elements behind the tines are also available for improved levelling, and specially shaped star wheels which resist blocking and mud build up can be fitted instead for optimal results in heavy soils.

The Karat 10 comes in mounted and semi-mounted versions and with working widths from 3–7m.

Increased performance is available through a traction booster and new ContourTrack, particularly when operating semi-mounted models in undulating terrain.

A wide range of sizes and types of rear packer can be specified.

New option

ContourTrack adapts the cultivator to maintain a constant working depth on undulating ground. Without it, the tine operating depth can be too deep when working across ridges, or too shallow when passing over localised dips. ContourTrack monitors the working depth at each side through the wheels, and an angle sensor monitors the relative working positions of the front and rear cultivation elements and constantly adjusts to maintain the pre-set working angle and depth. This is a particular advantage for ultra-shallow tillage where a difference of just a few centimetres working depth is significant.

ContourTrack can also be used to match the cultivator depth settings with information from field contour maps for automatic adjustment. A tractor with TIM (tractor control by implement) is needed, which also includes rear linkage adjustment.

The new Juwel 8i plough offers simple operation from the cab. Working profiles can be set and stored for easy recall.

Intelligent ploughing

A new Juwel 8i plough with Isobus control was displayed, featuring Lemken’s IQ plough control system.

Demand for Isobus plough control is increasing, allowing convenient adjustment of rotation, inclination, working width and working depth from the cab. On-plough hydraulic systems mean only three hose connections to the tractor, saving time.

Up to eight working scenarios can be stored for recall and activation at the touch of a button. Examples of benefits include ensuring the last furrow is kept shallow when ploughing the headlands to avoid deep cross-furrows. Hydraulic inclination adjustment of the plough can be made independently on the right and left to produce an optimal ploughing pattern in all conditions.

Like the Juwel 10; the Juwel 8i can be moved on the road with the top link in place. With the single transport wheel taking the plough’s weight in the butterfly transport position, the frame swivel cylinder can be depressurised allowing free movement over uneven ground.

Deliveries of the Juwel 8i start in March.

A new Heliodor cultivator with a factory-fitted slurry applicator has been added to meet customer demand.

Factory-fitted slurry applicator

Lemken has added a slurry application system to options available for the Heliodor discs, for easy and reliable operation with self-propelled or trailed slurry tankers.

Improved road transport

A transport wheel to reduce weight on the tractor rear axle is a new option for the OptiDisc25.

Lemken Agri drill training specialist Lukas Bonus, Lemken UK general sales manager Paul Creasy and Lemken Ireland area sales manager Derek Delahunty are pictured (l-r) with the new Solitair DT.