Spring seedbeds benefit from specialist cultivator

1st June 2022

A Suffolk sugar beet grower trialled a high-specification seedbed cultivator this spring, to find out whether it offered significant advantages over the farm’s usual power harrow-based system. David Williams reports.

A 6m Lemken Kompaktor seedbed cultivator was trialled this spring by Suffolk-based Rougham Estate Farms.

Lemken’s Kompaktor seedbed cultivator is designed to crumble, reconsolidate, and level soils, leaving an ideal seedbed for spring drilling. The manufacturer claims that it creates ideal conditions for planting fine seeds such as sugar beet, onions, and oilseed rape.

Fine, level seedbed

The Kompaktor is available in working widths from 3–12m, and in rigid, foldable and foldable semi-mounted versions.

The 6m semi-mounted model supplied for the trial had four 1.5m roller and tine sections suspended from the main frame. Sections are individually mounted, allowing movement over and around obstructions.

Each section consists of a pair of 270mm flat bar rollers, two levelling boards and three rows of spring tines. The rollers form the running gear, and there is one at the front of each section and the other at the rear – with the three lines of tines mounted between. Working depth is set by adjusting the height of the tines relative to the front and rear rollers. A single adjustment is needed to set each tine bank and a parallelogram linkage ensures tines adjust evenly across the length and width.

Hydraulically adjusted levelling boards behind the front and rear rollers remove peaks and fill in troughs, and shatter clods thrown by the rollers.

At the back of the cultivator, a large 400mm crosskill packer roller crushes remaining clods and consolidates the ground, leaving an ideal surface for drilling.

The Kompaktor is designed to create a fine, level, and consolidated tilth ideal for drilling small seed crops.

Range of soils

Rougham Estate Farms, near Bury St Edmunds, Suffolk grows approximately 1,100ha of arable crops on a mix of owned and contract-farmed land with soils ranging from very light sand to heavy clay loams. Sugar beet is grown as a break crop on all soil types. Reduced margins in recent years have highlighted the need to optimise growing conditions to maximise yields but creating ideal seedbeds can be challenging, especially on heavy clay soils. For many years, power harrows have been used as they work in almost any conditions and can be relied on to leave an acceptable finish.

“We know that we can rely on power harrows to create a tilth, but they need a lot of power and fuel, and are very slow,” stressed Rougham Estate Farms arable manager Paul Cornwell, who also has his own agricultural contracting business specialising in planting and harvesting sugar beet. “We were keen to find out how the Kompaktor performed on our range of soils, and whether using it rather than the power harrow would produce a better seedbed for our sugar beet.

“Higher work rates were expected – which would give us added opportunities to prepare land quickly for drilling when weather windows occurred. We are also keen to exploit any opportunities to save fuel which has become a priority as prices are currently so high.”

Light land planting

On the lighter land, over-winter cover crops had been established after wheat or rye, and then sprayed off ahead of a pass with a low disturbance subsoiler.

Exceptionally dry conditions meant that the bar rollers penetrated well below the surface, and the tines had to be raised to prevent them working too deep. A large volume of loose, dry soil built up occasionally in front of the levelling boards, but hydraulic adjustment from the cab meant the operator could make fine adjustments on the move to keep the soil flowing. The two side panels prevented soil spilling out from the machine and bouts were perfectly matched without ridges or troughs. The Kompaktor worked well, and consolidation by the flat bar rollers and rear press helped retain valuable moisture.

The 6m cultivator is made up of four 1.5m sections. Each section has three rows of tines between a pair of rollers – one at the front and the other at the rear. Levelling boards follow each roller, and hydraulic adjustment from the cab means the operator can raise or lower them to adjust the amount of soil able to flow through. A rear crosskill packer roller crushes clods and reconsolidates the ground.

Heavy land challenge

The heavier land grew wheat last year, and stubbles had been sprayed off and then ploughed and pressed before being left over-winter. Dry weather during the weeks before cultivation meant that the surface had become hard and cloddy, creating a challenge for the Kompaktor. “Some of the ploughed and pressed ground was very hard on top, and after a single pass the spring tines hadn’t penetrated as much as we had hoped,” commented Paul. “We used the power harrow to prepare some of the land, and made a double pass with the Kompaktor elsewhere which proved successful. Even where two passes had been needed, preparing the land with the Kompaktor was still faster and cheaper than a single pass with the power harrow.”

The three rows of tines between the rollers are mounted on a parallelogram linkage. This means all the tines adjust as a group to work at equal depth.

Clods less of an issue

Paul said that the dry conditions and heavy soils produced clods which were very difficult to break down. “One of the main advantages of the Kompaktor is that any clods not broken or crushed are left on the surface. When we drilled behind the Kompaktor, the clod deflectors were able to push lumps on the surface to the side, leaving a fine tilth for the opener to work in, and to surround and cover the seed.

“There were fewer clods to be seen on the surface where the power harrow had been used, but when we dug down to check the seed rows it was obvious that the clods were mixed in with the finer tilth around the seeds instead. The rotary blade action had distributed the remaining clods throughout the working depth,” he confirmed. “Fine tilth around small seeds in the rows is needed to ensure optimal seed to soil contact, so the Kompaktor achieved better conditions for early and even establishment.”

Wheeltrack eradicators at the front of the cultivator easily removed compaction behind the tractor’s dual wheels, and the field surface was left level and ideal for drilling. “Rather than lift the cultivator onto its transport wheels for headland turns, we left it in the ground,” said Paul. “It turns easily, and the headlands are worked during each turn. Compaction is reduced, and in sticky conditions the rollers keep turning and remain clear of soil.”

Impressive fuel savings

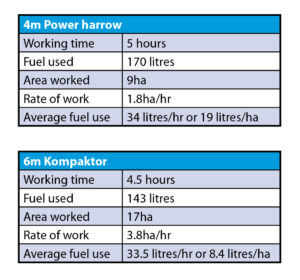

Fuel comparison figures were obtained for the tractor with the Kompaktor, and with the power harrow.

The Kompaktor requires very little maintenance. All the main bearings are sealed for life, and the only grease points are on the folding pivot points – and need lubricating once per season. The ball on the lower linkage hitch point should be greased weekly.

For transport – the Kompactor folds for transport in under a minute and Paul said it tows well behind the tractor at high speeds on the road.

Not just for sugar beet

Lemken area sales manager Steve Plumb arranged the cultivator’s loan and helped to set up the machine on its arrival at Rougham Estate. “The Kompaktor is well established, and most of those working in the UK are in the Eastern Counties and East Anglia,” he explained. “It’s probably the best cultivator for preparing land for sugar beet, but the working principle and seedbed finish makes it ideal for other crops too, and we have supplied them to onion producers and to turf growers who also require the level finish and fine tilth.

“It’s a very versatile machine and it will achieve high work rates. Once a farm has invested in a Kompaktor – then we often hear of it being used to prepare seedbeds for a wide variety of spring crops.”

Side guards keep moving soil within the confines of the cultivator at typical working speeds of 12–14kph. Perfect bout matching is achieved without ridges or troughs at the join.

Increased flexibility

Paul said that during the long-term demonstration, the Lemken cultivator had proved easy to set up and use. Once a suitable depth setting was identified, then the only time it needed changing was when moving between light and heavy soils.

“I was impressed by its performance, and especially the high rate of work which means that enough land can be prepared in just a few hours to keep the beet drill working all day. It produces a good, well consolidated seedbed and it leaves the land level. Compared to the power harrow, it’s also quieter, more comfortable and it achieves a better finish too.”

Pictured with the Lemken Kompaktor are Lemken UK area sales representative Steve Plumb, and Rougham Estate Farms arable manager Paul Cornwell.