See how Somerset boutique hotel produces home-grown flour

28th March 2024

The Newt in Somerset, a part of the Newt Estate, which was recently named one of the best boutique hotels in the world, took on a challenge to supply its restaurants with ingredients grown, foraged and reared on the site. The processing of its own heritage wheat will enable home-grown flour to become a valuable additional ingredient.

The Newt Estate’s farm manager, Cameron Knee, explained: “As well as Einkorn and Emmer heritage wheat, we grow feed wheat and barley for our 400 pedigree British white cows, of which we are very proud as it is the biggest pedigree British white herd in the world, our 350 pedigree Dorset down ewes, and our herds of red and fallow deer.”

To process the heritage wheat, Newt Estate’s project manager, Ed White, was looking for a dehulling plant and already negotiating with a provider of post-harvest equipment when a neighbouring farmer recommended that he talk to McArthur BDC.

The realisation by both managers that McArthur BDC could deliver a more compact and cost-effective solution resulted in the company working closely with the Newt Estate to design a processing plant to meet the estate’s requirements.

Cleaning wheat

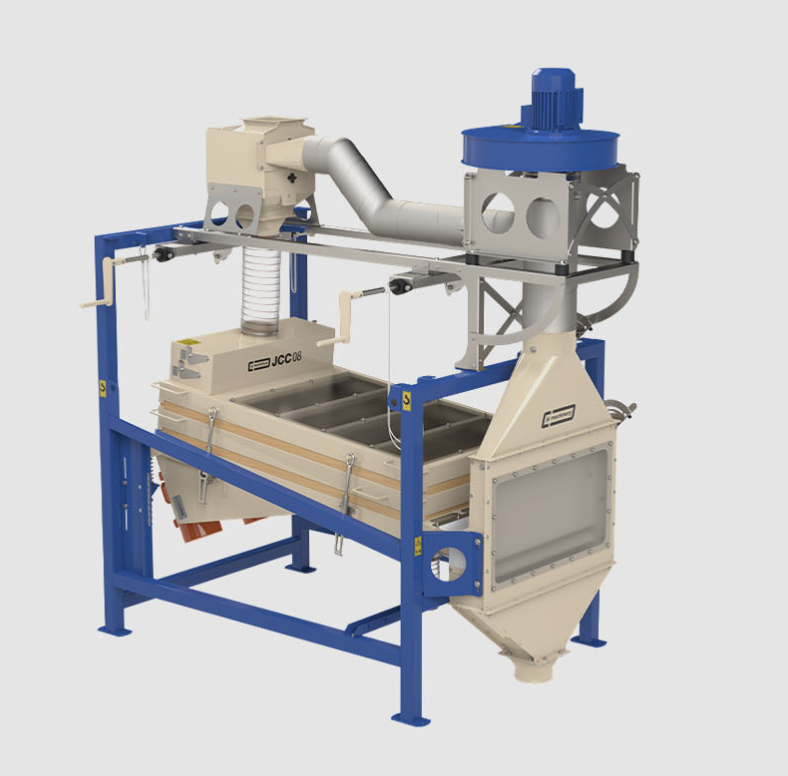

A JK Machinery JCC05 VibroCompact sieve cleaner, with the capacity for a quick pre-clean of up to 6tph or 1.5tph for a detailed clean, was installed to clean the wheat and prevent harmful material from entering a JK Machinery JHC03 Compact Dehuller. The JHC03 has the capacity, depending on the grain, to dehull between 400kg/h and 1tph.

Mr Knee said: “As we are dehulling wheat, the JHC03 was our preferred machine as it uses impact to dehull rather than grinding. This is important when dehulling pointed-shaped crops, such as wheat and barley.”

The grain is transported from the sieve cleaner to the dehuller via two Astwell augers, each with a capacity of up to 3tph. Both the sieve cleaner and the dehuller are fitted with aspirators, and to ensure cost-efficiency, both operate with the same fan and cyclone.

Once the wheat has been dehulled, it again passes through the sieve cleaner, removing any remaining whole grains or husks not removed by the aspirator. The grain is then ready for milling and is discharged from the JCC05 sieve cleaner into 1t bags.

Mr Knee continued: “Our local miller operates a stone mill, which means he has exacting standards around the quality of the grain he is happy to mill. The McArthur BDC cleaning and dehulling system has meant that we have been able to not only meet his standards but exceed them, and he can’t wait to get his hands on some more.”

Cost-effective solution

The current system, which allows the estate to clean and dehull its heritage wheat on-farm, is just the start of its journey to add flour to the list of estate-grown ingredients used in its restaurants’ kitchens.

In around 18 months’ time, the existing processing plant will be moved to a specifically designed building, and Newt Estate will be making decisions around how to increase its cleaning and dehulling capability.

Newt Estate’s farm manager added: “Working with McArthur BDC, which has designed a plant that meets our existing requirements with a cost-effective solution that is simple to operate, we will be looking at potentially installing JK Machinery equipment with a larger capacity and the features and functionality to further reduce impurities within the grain.

“For any farming business looking at installing a grain processing plant, I cannot overestimate the importance of getting your preferred supplier to carry out a site visit to make sure that the design works within the available space.”

Mr Knee also advises getting a good electrician onboard from the start. It is important that they are comfortable working with grain handling equipment and can interpret specifications and drawings.

Read more machinery news.