Factory tour – New Holland celebrates 60 years of success in Basildon

17th April 2024

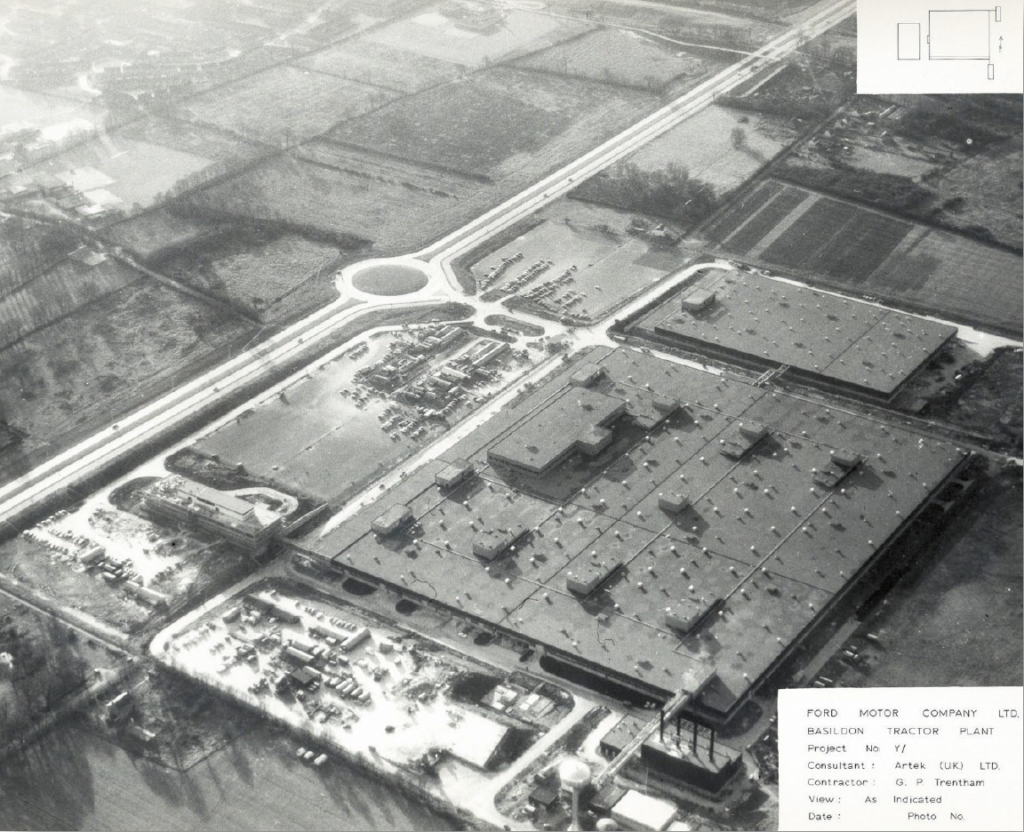

2024 marks the 60th year of tractor production at the Basildon plant of New Holland. Work started at the height of the 1960s, with the ground broken on the greenfield site of what was then a rural part of the Essex countryside in 1963. Basildon has changed significantly over those 60 years and the tractor plant is now located in the centre of a what has become a large urban conurbation, as a crucial local employer.

Origins of the brand

Originally a Ford plant, the factory rebranded to New Holland in 1994. The company is named after the town in Pennsylvania USA where founder Abram Zimmerman opened a repair shop in 1895. He started producing agricultural equipment himself in 1903, the very same year that industrialist Henry Ford started building automobiles in Detroit, Michigan.

Ford quickly saw an opportunity to start manufacturing agricultural equipment and, in 1907, produced the world’s first mass-produced internal combustion engine tractor, the Fordson Model F. In Europe, Leon Claeys started making threshing machines on a site in Zedelgem, Belgium in 1906. 118 years later, this site is now New Holland’s harvesting centre of excellence.

In 1947, Sperry Rand Corporation bought New Holland and rebranded it as Sperry New Holland. Sperry Rand then bought out Claeys in 1964. Ford and Sperry New Holland continued on separate paths until 1986, when Ford purchased the New Holland machinery business from Sperry and became Ford New Holland Inc.

In 1991 Fiat, which had been in agriculture manufacturing since 1917, purchased Ford New Holland and rebranded it as New Holland Geotech, launching the ‘new’ New Holland to the world in London in 1994. In 1999 Fiat acquired Case Corporation and merged it with New Holland to create CNH Global – the company that today sells both New Holland and Case branded equipment.

History of production

Located just 20 miles from Ford’s large Dagenham plant, where over 1m Fordson tractors had been built in the preceding 31 years, building work on the Basildon plant was completed in 1964 at a cost of £20m – £200m in today’s money. The new building spanned over 1.3 million sq ft and included new road infrastructure to service and support the plant.

Production started in August of 1964 with 2,302 tractors completed by the end of the year. Tractor production ceased at Dagenham and now, fully up to speed, the Basildon plant was producing the first ‘Ford’ branded tractors with the 2000, 3000, 4000 and 5000 series in the iconic blue and white colour scheme. In the first full year, the factory turned out up to 300 tractors a day with 3,500 employees based at Basildon.

The 1970s saw the first turbo charged production tractor rolling off the production line, as well as the launch of the new 7000 series and the quiet Q cab. In the 1980s power had increased, meaning models were now available with over 100hp, while the factory introduced the first automation with a robot tasked with fitting ring gear to flywheels. This decade also saw manufacturing transferred to Basildon from the Romeo plant in the US and 1989 marked the 25th anniversary of the plant with a special ‘silver jubilee’ edition of the 7810 model produced.

During the 1990s, more powerful models were introduced, with options up to 160hp, and 1994 was the year when the last Ford oval was placed on a bonnet – to be replaced by the New Holland leaf. This was also a decade of further automation, with a new robotic paint floor introduced in 1998 and automated guided vehicles introduced onto the factory floor.

21st century developments

The first decade of the new millennium saw many new features added to the range to make the tractors more comfortable, user friendly, powerful and environmentally friendly, with the introduction of Stage 1 emission regulations, followed in quick succession by Stage 2 and 3.

Features that made their debut in this decade include power command full powershift transmission, SuperSteer front axle, Terraglide suspended front axle, Comfort ride cab suspension, auto command CVT transmission, engine power management, the Horizon cab and the cat-eye light bonnet design. In 2008, the very last Powerstar engine was built at Basildon, after 44 years and over 3m units. From this point onwards, New Holland moved towards the FTP industrial Nef engine.

During the 2010s New Holland launched the T6 and T7 ranges, implemented Stage 4a emission control and launched dynamic command. 2014 marked the 50th year of the plant and, again, special edition ‘golden jubilee’ models were produced in both the T6 and T7 rages with unique dark blue metallic paint, gold decals and a gold grill.

All models produced in 2014 had 50-year fender decals applied. Further developments of the site in this decade included a new customer centre with large showroom, a rolling road facility and a new cab line in the factory.

New Holland today and into the future

Most recently New Holland has continued development of its latest models, with a special emphasis on alternative fuels. Diesel powered tractors are now Stage 5 compliant, but the big developments have been with methane power.

New Holland T7 Methane Power CNG

In 2021 New Holland launched the world’s first methane powered tractor – a T6 model – and the facilities at Basildon have been upgraded accordingly with a dedicated methane sub assembly area as well as a methane specific pre-delivery inspection building.

While compressed natural gas (CNG) is the technology currently being used, the R&D department is currently working on liquid natural gas (LNG) technology. As well as upgrades for methane specific applications, the factory has undergone other changes to streamline production and improve efficiency in the last few years. Smart factory integration delivers a ‘just in time’ process of parts being delivered to the various assembly points as they are needed.

No two tractors are the same

Plant manager, Ryan Hopkin, explained during Farmers Guide’s tour of the facilities that, due to the number of options spread across the models, the repeatability of tractors on the production line is around 1.4 per year. This means that effectively no two tractors in any one year are identical, so the smart factory system allows the right parts to reach the right tractor wherever it is on the line.

RFID tags are used to monitor the circa 3,500 boxes of parts that move around the line every shift to help with accountability and traceability. Further improvements to the production line are being made all the time, and within the last two years there has been a new bonnet and cab manipulator added, as well as new robotic painting and monolaser paint facility.

It’s not just on the production line that better, more efficient practices have been introduced. The design team now have access to technology that the designers of the 60s and 70s could only have dreamed of. The large drawing boards have given way to modern 3D computerised design, digital modelling tools and 3D printers that allow prototype parts to go from a design to a physical test product in a matter of hours.

There are around 300 staff on the production line at any one time, working on around 160 tractors – many of which will be moving around on the 2.2km of monorail suspended from the ceiling. Each tractor will spend around 1.5 days on the line before being towed off the end and put thorough an extensive pre delivery inspection and testing on the Basildon test track.

Celebration of 60 years at Basildon

So, after the silver and gold jubilee models, what are New Holland doing for their 60th celebration? A diamond encrusted tractor perhaps? No, they certainly caught the gathered press and media by surprise when they brought out the special edition T7.300.

The company has delved into psychedelia to mark the decade where it all began in this corner of Essex. It may not be to everyone’s taste, and in fact it is more of a marketing gimmick than a real special edition offering; but we are reliably informed that, if you ask very nicely, you could be working the fields in your very own slice of the swinging 60s.

Read more machinery news.