JCB marks 80 years with tractor and telehandler launches

16th October 2025

JCB welcomed dealers and press to its Rocester headquarters this autumn for what is shaping up to be a significant anniversary year. Daniel Hodge reports.

With the company approaching 80 years since its foundation in 1945, the event served both as a celebration of heritage and a showcase of new product development.

Managing director John Smith acknowledged the volatile market conditions of recent years – tractor registrations across Europe have slipped since 2019, with the UK showing particular softness.

Yet he pointed to resilience in the materials handling sector and argued that JCB’s long-term strategy of “product leadership” required continuing to invest in new machines, even during uncertain cycles.

The day’s launches reflected that dual focus, with major updates in both tractors and Loadall telehandlers.

Fastrac market gap

One of the clearest themes in John Smith’s introduction was the way in which farms are consolidating their horsepower. While overall tractor sales are down, demand at the top end has remained firm, with buyers expecting fewer machines to do more work.

That is where JCB has long pitched the Fastrac. For more than three decades it has offered something different from conventional tractors: suspension on both axles, truck-standard braking, and higher road speeds, while still capable of pulling heavy implements in the field. Contractors in particular have found the combination appealing, especially when long road runs are part of the job.

Until now, though, the Fastrac range had a gap. The 4000 Series ends at 235hp, designed as a versatile multi-role machine, while the 8000 Series tops out at 348hp with 70kph road speed. That left a sizeable middle ground unserved. It is precisely that 240–330hp bracket that the new 6000 Series has been developed to fill.

The 6000 Series unveiled

The two-model 6000 range comprises the 6260, producing 284hp, and the flagship 6300 at 335hp. Both use a 6.7-litre FPT NEF six-cylinder diesel, producing 1,275Nm and 1,400Nm of torque respectively.

Importantly, around 95% of peak torque is maintained between 1,200–1,800rpm, giving what JCB’s engineers describe as “plenty of back-up grunt” when the revs dip under load.

Transmission is handled by the ZF Eccom 3.1 CVT, which covers four ranges with a high proportion of mechanical drive at typical field and transport speeds. The design means uninterrupted acceleration up to 66kph, avoiding the shift from field to road range familiar to most CVTs.

The tractors carry a new chassis design, with a cast front section and fabricated rear. This accommodates an 11t rear lift and optional 5t front linkage, alongside a new 1,000rpm reversible PTO shaft. Weight distribution remains the familiar Fastrac 50:50, intended to improve both traction in the field and stability on the road.

Tom Mowforth, product manager for Fastrac, told attendees that the project began more than five years ago and represented the largest single investment JCB has made in its tractor business. “The brief was to create something with the strength and power of the 8000, but in a more compact, manoeuvrable package,” he said.

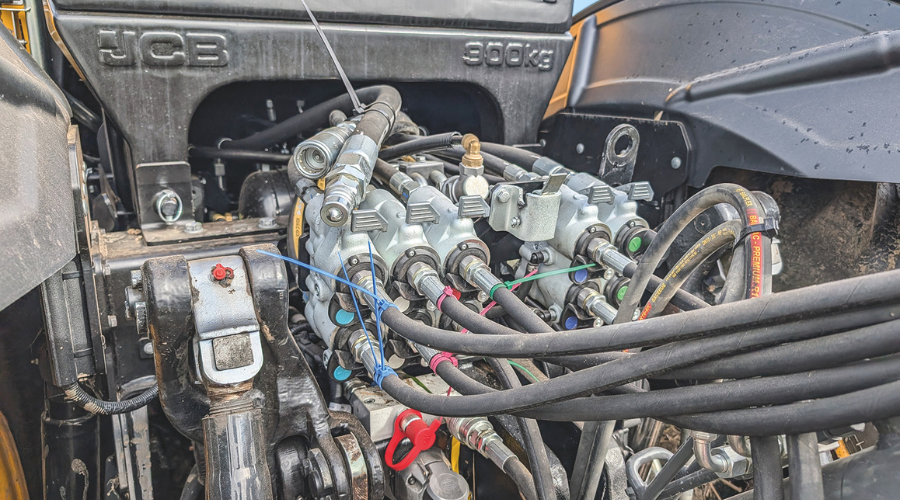

Hydraulics and PTO options

Hydraulic demand has risen steadily with the size of implements, and the 6000 Series reflects this.

A 205-litre/min variable-flow pump is standard, with an optional twin-pump system on the 6300 delivering up to 410-litres/min. Separate hydraulic oil and transmission circuits reduce the risk of contamination.

The tractors can be fitted with up to seven spools, connected via couplings that allow under-pressure connection. A Power Beyond circuit is also available.

At the rear, the 11t three-point linkage is attached directly to the axle to maintain suspension movement under load. The PTO is four-speed, while the optional front PTO includes a reversible six- or 21-spline shaft.

JCB’s engineers described the reversible shaft as a small change with practical value, enabling a wider range of front-mounted equipment to be used without adaptors.

Central tyre inflation system

The 6000 also introduces a fully integrated central tyre inflation system (CTIS) – the first time JCB has fitted one to a tractor. Twin compressors supply 600 litres/min of air, routed through single lines within the axles. This avoids external pipework, reducing the risk of damage from hedges or gateposts.

Switching between field and road pressures can be done in a matter of minutes. JCB’s figures suggest four minutes to inflate from 1 bar to 2 bar, and less than a minute to deflate.

Operators can make the change on the move, meaning a tractor can leave the field at low pressure and be ready for the road by the time it reaches the lane.

The benefits are familiar to those using CTIS on other machines; improved traction and less slip in the field, combined with reduced compaction. On the road, higher pressures improve stability and extend tyre life.

Suspension and steering

Another focus has been steering and ride. The 6000 carries hydro-pneumatic suspension front and rear, allowing the tractor to “squat” under heavy implements or demountable equipment such as a sprayer.

Four-wheel steering is standard, with multiple modes including true tracking and rear delay, useful when manoeuvring long trailed implements into tramlines or gateways.

Unlike the mechanical lockout on the 4000 Series, the new tractors use a progressive hydraulic system. As speed rises beyond 17kph, rear-wheel steering phases out gradually, giving what JCB engineers say is a smoother transition to stable two-wheel steering at road speed.

Braking and safety

At 66kph, braking performance is a central issue. The 6000 introduces single-calliper outboard discs on all four wheels, replacing the twin-calliper design of previous Fastracs. JCB says this change addresses noise and vibration seen in testing, while also improving serviceability.

Replacing pads and discs can be done in around three hours, compared with the day or more typically required on inboard systems. Outboard discs also aid cooling, helping to keep braking consistent.

Wear sensors on each corner alert the operator before pads deteriorate – believed to be an industry first for tractors. ABS is standard, along with a trailer ABS socket.

Endurance testing

between 1,200–1,800rpm in the 6260 and 6300.

The tractors have been in endurance fleets for more than two years, accumulating hours in real farm conditions rather than just test tracks. Feedback has come from customers in the UK, Germany, the US and beyond, with Tom Mowforth describing his role as a “translation service” between the field and the design office.

According to JCB, feedback on horsepower, soil protection and manoeuvrability all fed directly into the design. Demonstrations at Rocester showed the GPS system in action, with twin receivers giving quicker line acquisition and automated headland turns.

New Loadalls expand the line-up

The tractor launch was followed by additions to the Loadall range. The 546-70 and 555-70 build on the 542-70, offering more capacity without increasing machine size.

The 546-70 lifts 4.6t, about 9% more than the 542-70, while the 555-70 reaches 5.5t, nearly a quarter more. Both machines share the 7m lift height.

Power comes from 130–173hp DieselMAX engines. AGRI Super and AGRI Xtra versions use a 40kph DualTech VT transmission, while AGRI Pro specification raises this to 50kph. DualTech’s hydrostatic control at low speeds switches seamlessly to powershift for higher speeds, aiming to balance precision around buildings with efficiency on the road.

AGRI Pro models also engage four-wheel drive under braking, while air trailer brakes are available as a factory fit. A Sway Control system (previously limited to larger machines) is now offered, allowing the chassis to be levelled from the cab on uneven ground.

IntelliAssist and IntelliWeigh

The new handlers also introduce operator support systems. IntelliAssist offers automation for repetitive boom movements, such as height and reach limits, or return-to-dig and return-to-load positions. Auto boom extension and retraction help keep attachments on a straighter path when stacking.

Hydraulic refinements include adjustable flow to soften control response and an Inverse Front Auxiliary function that reverses oil flow without swapping hoses.

IntelliWeigh provides integrated weighing using hydraulic pressure and boom position, rather than external load cells. It can record individual bucket weights, total loads, and set target weights to prevent overfilling feeders or trailers. Data links to JCB’s LiveLink system for record-keeping and analysis.

The systems are optional, but JCB suggests they will appeal both to less experienced drivers, by reducing the chance of error, and to contractors seeking greater consistency across their fleets.

Closing thoughts

Between the Fastrac 6000 Series and the two new Loadalls, JCB has targeted two areas of demand it believes are growing: higher horsepower tractors with transport capability, and smarter telehandlers with more operator support.

Both launches were presented as part of an ongoing feedback loop between JCB engineers and customers. With Agritechnica 2025 approaching, and the company’s 80th anniversary on the horizon, the Rocester event was as much about showing that process as it was about unveiling machines.

Farmers and contractors will now decide whether the new tractors and handlers deliver the mix of power, technology and practicality they require.

Read more machinery news.