New flagship test drive highlights performance and features

30th May 2024

The first line of Valtra’s latest flagship S6-series tractors have arrived in the UK, following the new model’s launch at Agritechnica last year. Farmers Guide took advantage of an early test drive. David Williams reports.

As well as the new tractor, Valtra took the opportunity to demonstrate several new innovations available through its Unlimited Studio. These included an automatic levelling device for linkage-mounted fertiliser spreaders and a camera system which uses artificial intelligence to scour images and alert the tractor operator to potential hazards. There was also a demonstration of new automatic headland turn modes available to be added to Valtra’s SmartTurn system.

S6-series

One of the main differences between the new S6-series Valtras and their S4-series predecessors is that the latest models are manufactured at Valtra’s own factory at Suolahti in Finland. This has been made possible by major investment in the plant, including a new paint shop capable of accommodating the larger tractors. Valtra expects that bringing manufacturing in-house, including the transmissions, will add to the new tractor’s appeal and help it increase its overall market share from the most recently quoted figure of 7.1% early last year, almost 2% higher than a decade before.

New engine, cab and transmission

While the change in manufacturing location is significant, the new S6 tractors also feature a new cab, as well as an upgraded engine and transmission.

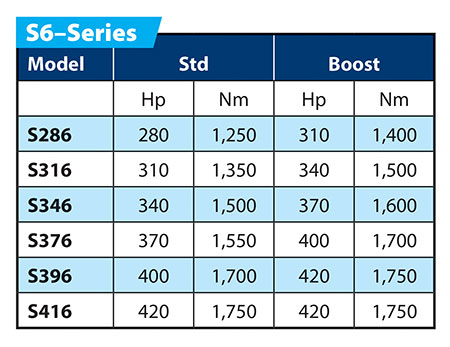

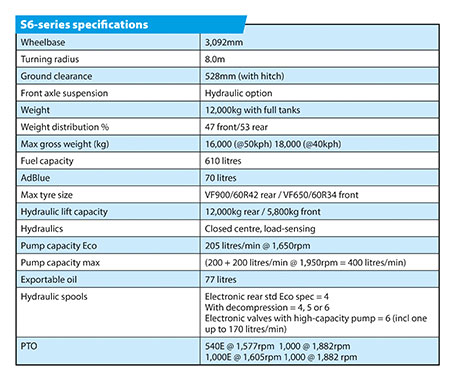

There are six models from 280–420hp. The new AgcoPower 8.4-litre engine meets latest Stage 5 emissions standards using SCR (AdBlue) but avoiding EGR. This improves combustion efficiency and means the engine runs cooler, making it more fuel efficient with significantly less power consumed by the cooling system.

A single turbocharger replaces the previous twin turbo set-up, and the long-stroke engine develops maximum torque at only 1,500rpm, and maximum power at 1,850rpm: approximately 5% lower revs than the previous S-series tractors. The most powerful S416 has maximum power and torque always available, while the other models achieve maximum power only in boost mode, which adds 20–30hp under specific operating conditions. The S416 produces up to 1,750Nm of torque – 9% more than the previous flagship while fuel consumption is reduced by 3%.

CVT standard

Although the transmission is similar to before, in the new tractors the ML260 CVT unit features upgraded hydraulic pumps providing up to 400 litres/min, a heavier-duty PTO drive train, and the rear axle diameter is increased to 125mm to handle the higher torque. Two operating speed ranges maximise efficiency for both field work and transport. The manufacturer claims that combining the new engine with the updated transmission increases efficiency, resulting in average fuel consumption up to 10% lower than the S4-series predecessor.

Valtra family cab

The cab frame and interior layout closely resembles current N-, T- and Q-series models. Heating and cooling performance is significantly better than the previous S4-series cab as air is distributed through 15 vents at different locations and levels, rather than only downwards from the roof.

Operator comfort can be optimised with a range of suspension options for the front axle and cab, and a choice of seats.

Valtra’s popular swivel seat and TwinTrac reverse drive controls are available, and a Skyview cab is an option.

LED lighting is standard, and various upgrade packages can be specified.

SmartTouch precision farming

The SmartTouch user interface is available with features including SmartTurn automatic headland turning. There are four turning patterns included – Part Field Mode, U-Turn, Y-Turn and K-Turn.

Isobus-based Tractor Implement Management (TIM) is planned for release for the S6-series in 2025.

Test drive

Although recent wet weather meant it was too wet for cultivations, the test drive venue on a disused airfield provided plenty of opportunity to utilise all 420hp and 1,750 Nm of torque of the most powerful S416. One tractor was hitched to a dump trailer loaded with 28t of aggregate, and another powered a large woodchipper.

For static power-hungry applications such as chipping, the S416 is ideal with maximum power and torque always available through the PTO drive to the chipper. The Valtra seat swivels 180 degrees, giving the driver a good view through the large rear window to the loading crane of the chipper. An even better view is available through the optional panoramic cab, although this wasn’t fitted to the demonstration machine. Inside the cab, the noise levels remained very low while the tractor management system easily maintained a constant PTO speed as the working load varied.

Several miles of private roads provided a good test of the Valtra S416 including its pulling power and manoeuvrability. The stepless CVT transmission reacted smoothly and efficiently during accelerating and braking, and the most suitable drive ratio was always available the instant the accelerator was pressed. Acceleration with the heavy trailer was impressive. The operator can easily swap between the foot accelerator and joystick at any speed and set the cruise control just by pushing the joystick to the right.

Some sections of the old concrete tracks were potholed and uneven, but the axle, cab and seat suspension ensured a comfortable ride.

An excellent all-around view from the seat, the small diameter padded steering wheel and the tight steering angle make the tractor feel exceptionally nimble for its size. Sitting in the driver’s seat, and looking forward along the compact bonnet, it doesn’t feel like a typical 420hp tractor.

Valtra view

Valtra area sales manager for south-west England, Gareth Jones, told Farmers Guide that the new S6-series tractors will be popular within the high power market sector. “For the first time, we will have the same driveability features including an identical cab and controls across all our tractors from the N5-series up, and that will increase appeal to those running fleets of Valtra tractors.

“Being built in the Suolahti factory is also a big attraction, and that will give extra confidence to our dealers and their customers who have great respect for Finnish manufacturing. Those who have driven the tractor so far were surprised by how nimble and responsive it feels. The engine and transmission combination works extremely well. The cab is a great working environment, and it is already popular on our N-, T- and Q-series models. I’m sure our new flagship will be very successful.”

Keeping the spreader level

Valtra’s Smart Top Link is available through the Unlimited Studio, and its primary application is to ensure that mounted fertiliser spreaders remain at a pre-set working angle, whether the hopper is empty or full.

“Typically, users set the spreader angle when the hopper is empty by adjusting the top link so that the spreading discs are horizontal. But, when the hopper is filled then the extra weight pushes the rear of the tractor down and the spreader discs tilt downwards at the rear,” explained Valtra SmartAg product specialist – engineering, Leon Powell. “This results in an uneven spread pattern, and it’s estimated that the effect on crop yields equates to a reduction in margin of approximately €20/ha.”

Valtra’s Smart Top Link utilises radar sensors attached under the front and rear of the spreader which measure distance above the ground, and an additional hydraulic block between the tractor spool and hydraulic top link. The system is set and controlled through the in-cab SmartTouch terminal, connected by an Isobus link. Once the spreader is attached and the spreading discs are horizontal, then the system is calibrated, and the disc angle is displayed on the screen. As the hopper contents vary the system senses the change in spreader and disc angle and extends or retracts the top link to keep the spreader horizontal.

“Six trial units have been working across Europe and the results and customer feedback have been extremely positive,” said Leon. “We don’t claim that it will recover the full €20/ha, but improved performance equivalent to €15/ha is probably realistic, which means a farm growing 200ha of wheat would see the £4,000 cost recovered within two seasons.

“There is no limit in terms of potential applications for the Smart Top Link, and development work is ongoing to extend its use to maintain optimum working angles for implements such as cultivators and hoes too.”

Smart camera system increases safety

Valtra also demonstrated its Unlimited View system. This utilises three high-definition cameras, a dedicated in-cab display, and artificial intelligence software to analyse images and identify potential hazards close to the working area. The usual set up is to mount two cameras right at the front of the tractor on a front loader, linkage-mounted implement or weight box, with one angled left and the other to the right. A crystal-clear view from each camera is permanently displayed on the screen, but as soon as potential hazards are identified then these are highlighted on the image within a red border.

The AI-based recognition system is so clever that even just a single hand sticking out from behind an obstruction is enough to generate a warning that a person is present, and at the event cardboard cut-outs of people were recognised and highlighted. Obvious applications include loading and manoeuvring in confined working areas, or when pulling out of field gateways on to public roads where hedges or trees obstruct the view from the cab, explained Abina Mahalingam of UX Designer Engineering. The operator selects what type of hazard should be highlighted, out of humans, animals and vehicles (including bikes). He can also select the area of coverage; the Valtra event included a simulation of a car travelling behind a tractor on a road. While directly behind, no warning was given, but as soon as the vehicle pulled out to the right preparing to overtake, then the system highlighted the risk and position.

Available from the Unlimited Studio, the Unlimited View system including the display and three cameras costs £3,600. It’s a very effective and practical safety feature.

SmartTurn upgrades

New headland turn strategies have been added to Valtra’s SmartTurn, which automatically steers the tractor around the most efficient path at the field headlands. U-turn and Part Field-Turn strategies were available previously, but Y-Turn and K-Turn can now be added free of charge through a software update for any 4th or 5th generation tractors with a SmartTouch display and any guidance system.

Also available is Auto U-Pilot, which automatically triggers the headland management sequence according to the tractor’s position relative to the inner border.

Dealer view

Several dealers were present at the same time as Farmers Guide, and for most it was the first time they had driven the new tractors. Shropshire-based Edwards & Farmer Ltd representatives Doug McGowan and Olly Mycock are pictured with the new S416. “It was the first time I had driven the S6-series,” confirmed Olly. “The transmission is exceptionally smooth and puts the power down to the ground well pulling the heavy trailer, and the ride at higher speeds on the bumpy concrete test tracks was excellent. As soon as you get in the cab, the Finnish build quality is evident. It’s got the same user-friendly SmartTouch terminal used in other Valtras and it makes it easy to utilise top level precision farming technology. There is plenty of space, very good visibility, and the controls are ergonomically designed.

“Based in Shropshire, our trading area includes many sheep and dairy farms as well as traditional family mixed farms but we also have larger arable farms, for which the new S6 will have plenty to appeal. Several of the previous S-series tractors operate woodchippers in our area, so the latest version will be a natural replacement. The improved engine and transmission arrangement, the addition of the popular Valtra-designed cab and the Finnish build quality gives us a new more powerful tractor to offer to complement the Q5-series, and it will easily compete with other brands in this power class.”

Right tyres, correct pressures

Trelleborg field sales engineer, Jimmy Jones and south of England sales manager, Craig Churstain also attended. The tyre specialists were at the Valtra event to advise farmers on tyre choice, and to highlight the need for correct inflation pressures. A Valtra tractor with a mounted 5f reversible plough was parked with the rear wheels on weigh pads. When the plough was lifted, the total weight on the rear tyres remained within their stated capacity; but when the plough was turned over, simulating headland turns, then the right-hand rear tyre was overloaded by more than 1.5t.

“It’s easy to overload tyres without being aware that it’s happening,” stressed Jimmy. “All aspects of use should be considered, and investing in VF tyres capable of carrying higher loads at higher speeds and at lower pressures is often a worthwhile strategy, while adding a Central Tyre Inflation System brings additional benefits making it easier to optimise pressures and performance for all situations.”

Read more machinery news