Unlocking the value of precision agriculture

24th July 2025

In an industry where data has long been touted as the key to unlocking higher yields and more sustainable practices, it’s easy to forget that simply collecting the information isn’t enough. According to Tuckwells’ technologies manager Kris Romney, the real value lies in how that data is used.

“Farmers have been creating and capturing data for years now, whether that’s yield maps, seeding rates or drilling dates,” Kris explains. “But collecting data is only worthwhile if you actually use it to inform decisions in a timely manner. Otherwise, it just becomes another job that doesn’t deliver value.”

This focus on practical application is central to what Kris and his team do. Increasingly, his team helps customers move beyond simply gathering data to genuinely integrating it into farm management.

The rise of protein mapping

One standout innovation that Kris is keen to highlight is John Deere’s HarvestLab 3000, which has recently been fitted by Tuckwells to three X9 combines. This technology enables real-time grain sensing, measuring protein and starch content across different parts of a field.

The data is then automatically mapped back to John Deere’s Operations Centre platform, allowing farmers to see not only how much crop they harvested but also its quality by zone.

“Traditionally, protein analysis happens at the grain store, providing just a snapshot,” Kris says.

“With HarvestLab 3000, farmers can see variations across their fields in real-time. This opens up opportunities to segregate grain with higher protein to meet milling specifications or blend

it strategically to reach premium levels.”

Precision, efficiency, sustainability

Beyond harvest logistics, the data has longer-term implications too. By identifying areas with consistently lower protein levels, farmers can refine their nitrogen and general nutrition application strategies for following seasons to even up field performance and ultimately secure higher premiums.

Nitrogen is always a hot topic of conversation in farming circles and has become an even sharper focus recently following recent and significant price fluctuations.

Precision data allows growers to improve nitrogen use efficiency and tailor applications more closely to each part of their fields, minimising wastage and environmental impact.

“The most data-driven farmers are looking at nitrogen use at a very granular level,” Kris notes. “Combining protein mapping with yield and seeding data enables them to build a detailed nutrition plan.”

Kris comments that this approach supports both profitability and sustainability, reducing excess inputs while safeguarding soil heath and improving crop quality. As input costs continue to rise, these efficiencies become ever more crucial.

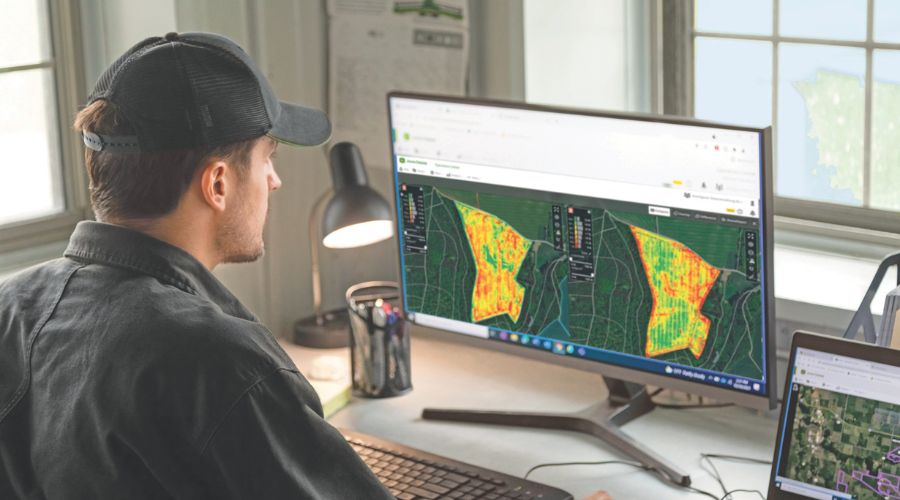

Operations Centre

Central to Tuckwells’ precision offering is the John Deere Operations Centre, a digital hub where farmers can bring together data from all of their machines, maps, and operations. While yield mapping is fairly ubiquitous on nearly all modern combines, the Operations Centre is enabling more advanced integrations.

“I have customers who have shifted their entire farm mapping onto the Operations Centre because it ties in seamlessly with their whole fleet and operation,” Kris shares. One customer even retrofitted John Deere yield mapping and steering on a competitor combine just so he had the ease of accessing all of his data on a single platform.

The system doesn’t just serve agronomy needs. Farmers are also using it for logistics management, tracking service vans, grain lorries, and field equipment during busy harvest periods.

“Knowing where all of your machines are, when they’ll be back, and even just how much fuel they have left in the tank can really streamline operations,” says Kris.

Predictive automation

When asked about the next big leap in precision agriculture, Kris points to automation, but not in the purely reactive sense most are familiar with. The latest and up and coming combines now feature predictive ground speed automation.

“Historically, combines adjusted speed reactively, slowing down when they detect greater crop mass, or adjusting based on engine load,” he explains.

Now, using biomass data from satellite imagery and onboard cameras, the combine can predict crop density ahead of time and adjust proactively. It’s about maximising efficiency before the machine even hits the thick crop.”

Kris suggests that this proactive approach is key for future autonomous systems, which will need to respond before issues arise rather than after.

Kris goes on to comment that technologies like ‘See & Spray” systems and camera-guided tractors will follow this predictive model, paving the way for fully autonomous fieldwork in the coming years.

Bringing farmers along

For many farmers, investing in advanced technology can feel daunting.

Kris emphasises the importance of seeing the benefits first hand: “We encourage customers to ask for demos. Our technology and demo teams love showing what these systems can really do. You can then clearly see potential cost savings and efficiency gains before making a decision.”

Ultimately, precision agriculture is a business decision. As farming continues to navigate pressures from rising costs and environmental scrutiny, Kris’ insights reveal that success lies in not just the data itself, but in having the confidence, tools, and support to use it effectively.

Read more business news.