Bauer to introduce new innovations at LAMMA

26th December 2023

The Bauer Group is set to launch a new E-series reel irrigator and irrigation boom cart – whilst its Fan Separator company introduces its biggest separator yet.

Austrian company Bauer will bring a range of new innovations to its LAMMA stand in January, including new E-series reel irrigations, which have several improved features to make operation and maintenance easier.

The most obvious visual change is to the side guard that covers the reel-drive turbine and gearbox – but less obvious is that instead of being held in place by 10 bolts, the new version has catches that when released allow the cover to swing away.

That makes it quicker and easier to access components such as the belt that transfers drive from Bauer’s water turbine to the pulley on the chain and sprocket that slowly rotates the drum to pull in the hose and either a rain gun or boom.

Opening the new cover also reveals a larger battery to power the Ecostar 6000 controller with its 4.3in LED touch-screen, which is supplemented by membrane buttons for the most frequently used functions.

Bauer UK & Ireland sales manager Adrian Tindall explained: “Users can store up to 12 different irrigation programmes that define retraction speed, pre-irrigation, post-irrigation and speed zones, and then retrieve them at any time to save having to enter individual parameters for every irrigation session.”

Remote access via SMS on a mobile telephone enables irrigation managers to not only stop and start the Rainstar irrigator remotely but also adjust retraction speed, check on the status of the machine and receive error messages.

A ‘run finished’ message can be activated, and thanks to a digital input on the irrigator’s water meter, the Ecostar 6000 controller also records the session and running total of water used.

The battery itself is now kept charged by a more efficient solar panel; it is still fitted flush to the cover but can now be propped at an angle to harvest energy from the sun more effectively.

Other changes include more easily accessible pipe drum bearings should they need attention and retrospective installation of brakes if needed is a new feature of the two- and four-wheel chassis.

The Bauer E-series comprises five models from the E 100 to E 500, each available with from seven to 11 different diameter and length combinations of Bauer’s own polyethylene (PE) pipe manufactured at the group’s principle factory in Voitsberg, Austria.

New irrigation boom cart

Bauer will also present its new lightweight AS 50 Neo boom cart that can be easily folded to transport width.

It is the only boom of this size that can be transported on the road together with the hose reel machine. And it weighs so little that it can even be folded in or out very easily, Bauer says.

There is currently a strong trend in the direction of low-pressure systems that conserve energy and resources. Many farmers decide to equip their hose reel irrigator with a boom cart instead of a wide-jet sprinkler to benefit from the advantages of low-pressure irrigation such reduced pressure for lower energy consumption, uniform water distribution, fine droplets that are easy on plants, low sensitivity to wind.

The newly adapted dimensions of the construction elements, the lightweight construction of the side sections and the innovative folding mechanism ensure the ideal width for road transport and even easier handling. Escort vehicles on the road are unnecessary; the boom cart is quickly opened and ready for use. This saves valuable time and money when transporting the boom from one field to another.

A big advantage of the new AS 50 Neo is the clearance height of 1m. This makes it ideal for crops grown by hilling such as potatoes or carrots. Another plus is the hydraulic height adjustment, a standard feature on the AS 50 Neo that is also used to raise it for folding.

Bauer boom carts are known for their tracking accuracy – which also applies to the new AS 50 Neo. Another major advantage is the energy efficiency of the low-pressure spray nozzles with which the boom cart is equipped, which determines the distribution accuracy. Most spray nozzles operate with a nozzle pressure of about 0.8 bar.

Additionally, the brand-new ‘end of system’ distribution device KPW (Komet Precision Wave) from Komet can be installed on both ends of the boom. The unique design of the KPW features an oscillating deflector to deliver exceptionally uniform droplet distribution. The more evenly the water is distributed, the greater the achievable yield.

The AS 50 Neo can be installed on all Bauer Rainstar models of the series E11 to E51 as well as the new series E100 – E600. Options such as the asymmetric four-wheel carriage, the 360° swivel mechanism and the levelling function are naturally also available for the AS 50 Neo.

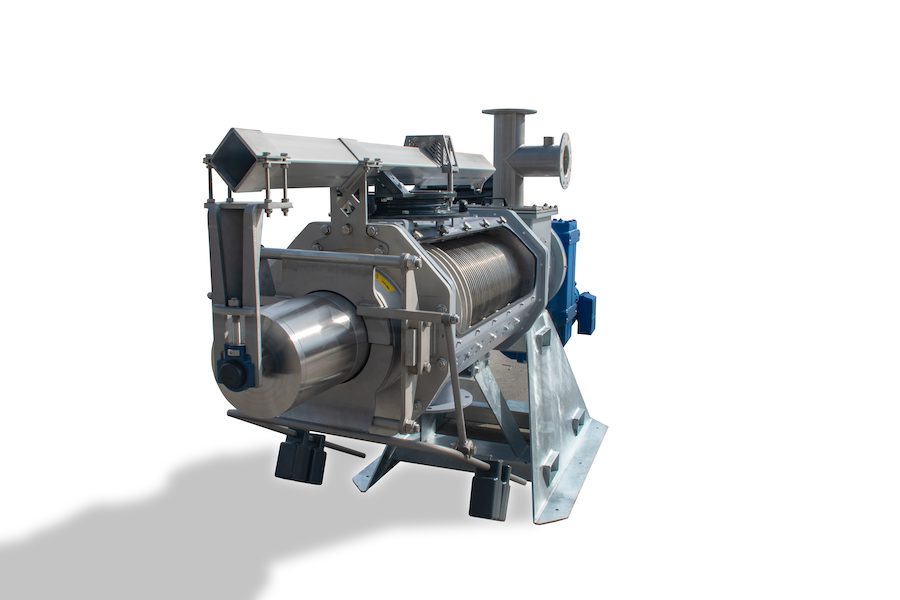

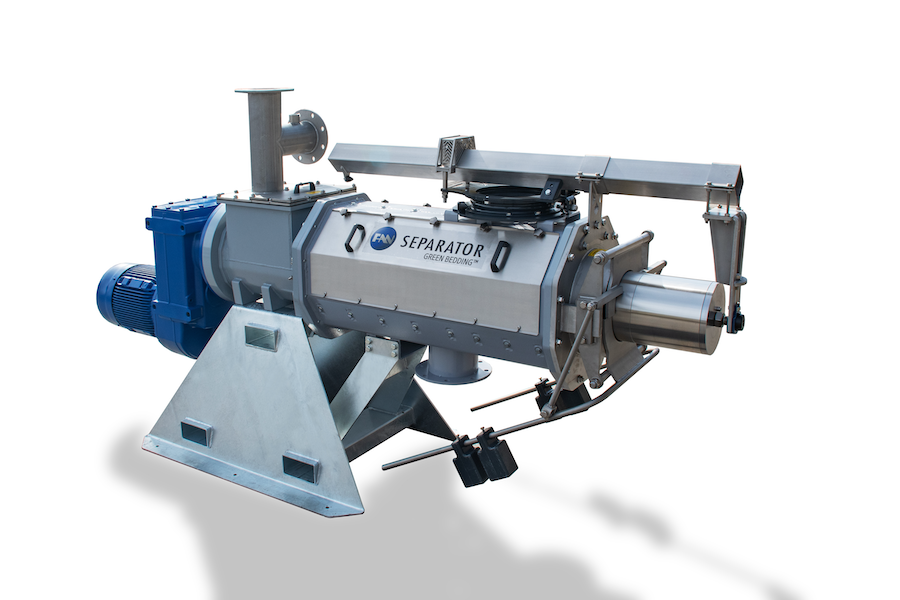

New press screw separator

With the new press screw separator PSS 8, Fan Separator is expanding its portfolio with a machine having sufficient capacity to replace two or three smaller machines, providing savings in energy consumption, manpower and peripheral equipment.

The high output of the new PSS 8, which is capable of 65cu m per hour, makes it suited to very large dairy farms wanting to ease the management, storage and field application of cow slurry, as well as for large-scale biogas production.

Separation of solids and liquids in farm slurry opens up effective and valuable options for further processing and reuse, especially as the solid material can be turned into compost or used as an attractive bedding material, particularly for dairy cows housed in cubicle sheds.

The liquid fraction, meanwhile, can more easily be managed, stored and spread on fields as fertiliser, one option being a ‘dirty water’ irrigation system.

With its impressive dimensions of 3.6m x 0.9m and height of 1.3m up to the inlet, the PSS 8 separator, developed for continuous operation on large farms, is an extremely robust machine.

The proven Fan press screw concept has been retained while the components have been enlarged: The 2200mm long and 350kg heavy auger is additionally supported by a head bearing. With a diameter of 400mm, the screen is also generously sized.

The built-in auger is driven by a 30kW electric motor running at 400V/50Hz.

Fed with cattle manure with a dry matter content of 7 to 9%, the PSS 8 achieves a throughput of up to 65cu m per hour, the moisture content or dryness of the extracted solids being varied by the number and position of counterweights using a patented output regulator.

Users can be confident of constant output and a high-quality material: the dry matter content, once set, remains unchanged throughout the entire period of use, with up to 36% dry matter content in the solids achievable consistently.

Like the entire Fan product range, the PSS 8 is built from carefully selected materials, with the screw featuring wear-resistant reinforcement, and all parts that come into contact with the slurry being made of stainless steel to ensure an exceptionally long lifespan for the machine.

Thanks to the floating screen bearing and the associated continuous cleaning of the screen by the screw, the PSS 8 remains almost wear-free even over long operating periods, and good access makes routine maintenance quick and easy.

With its large dimensions and increased throughput, a single PSS 8 can replace two or more smaller machines. Energy costs, space usage and labour in connection with operating the necessary peripheral equipment, such as pump stations, are all reduced.

This saves time and money, and decreases the environmental footprint.

Stand number: Hall 7, Stand 730

View LAMMA 2024 latest news, updates and top exhibitors to visit