Reducing ammonia emissions with air scrubbing systems

10th March 2022

UK poultry farms are increasingly being challenged by permitting requirements to reduce the concentrations of ammonia leaving houses. draperGROUP senior ventilation consultant Justin Emery provides some guidance.

About 65% of a bird’s total nitrogen intake is excreted, with 17% not digested and 48% not utilised. When litter moisture content is 25–35%, microbial action readily converts faeces into ammonia.

Best practice for limiting ammonia emission is to maintain dry bedding, with good internal air recirculation, air change helped by heat recovery, and much better climate control. With the correct installation, managed correctly, reduction of ammonia can be 30–50% on the UK standard broiler emission factor (0.034kg NH3/place/yr).

However, regulators are looking to stabilise the ammonia background count. They are juggling several, perhaps contradictory, aims such as minimising damage to the environment whilst encouraging food production (without incurring excess cost) and trying to encourage a reduction in energy use.

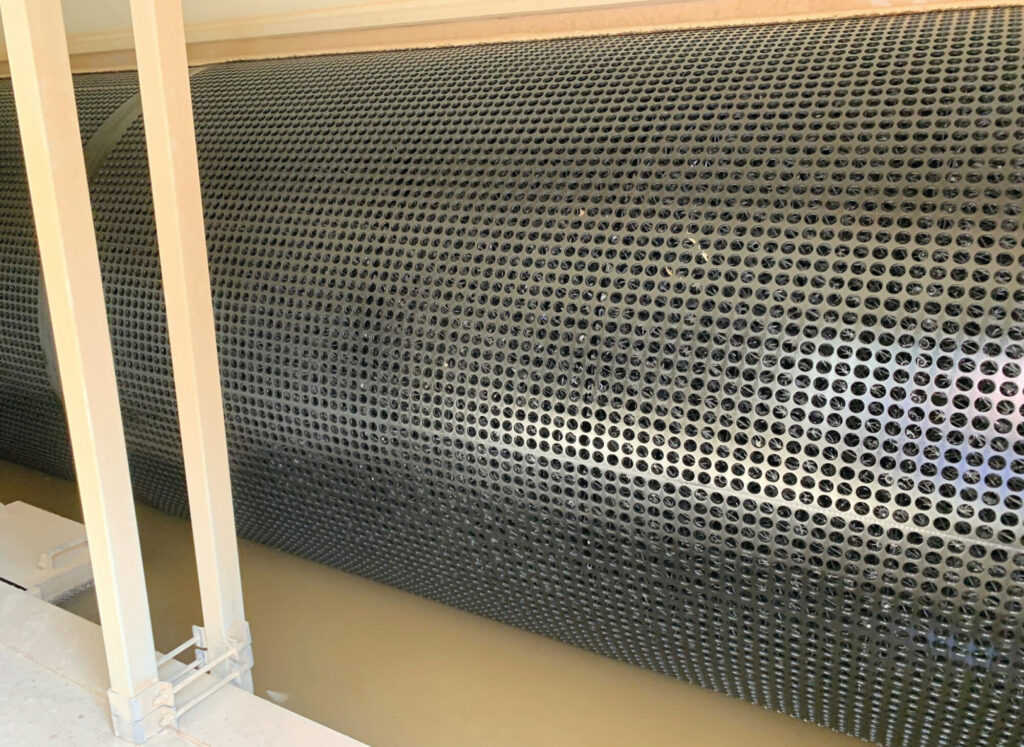

Reducing ammonia emissions using ‘acid scrubbing’ techniques has suddenly become a requirement for many proposed poultry farms in the UK, especially in Wales. Essentially, acid scrubbing involves passing exhaust air through a large matrix wetted by a solution of sulphuric acid and water, so that volatile ammonia is dissolved into the liquid, leaving the exhausted air much cleaner. Acid scrubbing is the most efficient and reliable ammonia removal system, with reductions of 90% possible for some applications, where sulphuric acid converts ammonia into an ammonium sulphate solution.

But this reduction is only achieved by incurring (in my opinion) excessive capital and energy cost to the farmer without, to date, meaningful consideration from the retailer and consumer. There is cost inflation across the board, but now inflation of means needed to tackle emissions.

There is limited online guidance from regulators, but detailed advice on how much to scrub tends to come from planning consultants and environmental modellers. How to ventilate and how to scrub comes from the equipment suppliers.

It is not all bad news. Farmers are tackling the issue and looking to build top-class farms that will be energy and emissions future-proofed.

This is new technology to the UK, so choose carefully:

- You are rearing poultry or pigs first – the ventilation and other hardware is ‘more important’ than the scrubber

- Find a system that integrates energy saving solutions e.g. heat – it is possible

- The scrubber equipment must meet the permit requirements

- UK regulators do not insist on one scrubber type, or one certification

- Acid is corrosive – the system must be resistant and durable

- The year-on-year running costs vary considerably between scrubber types, depending on the running costs of pumps – do check carefully.

To discuss further, you can contact the draperGROUP team directly for guidance.