Low establishment costs = low yields? Time to challenge this thinking

14th March 2022

It is a popular belief that by reducing your establishment costs and switching away from conventional methods, you reduce your yields. However, research conducted by AHDB indicates that this view can be challenged.

In its ‘Autumn Cultivations and Winter Crop Establishment’ study of 20 of its monitor farms, AHDB recorded costs against yields with some interesting findings – see graph below.

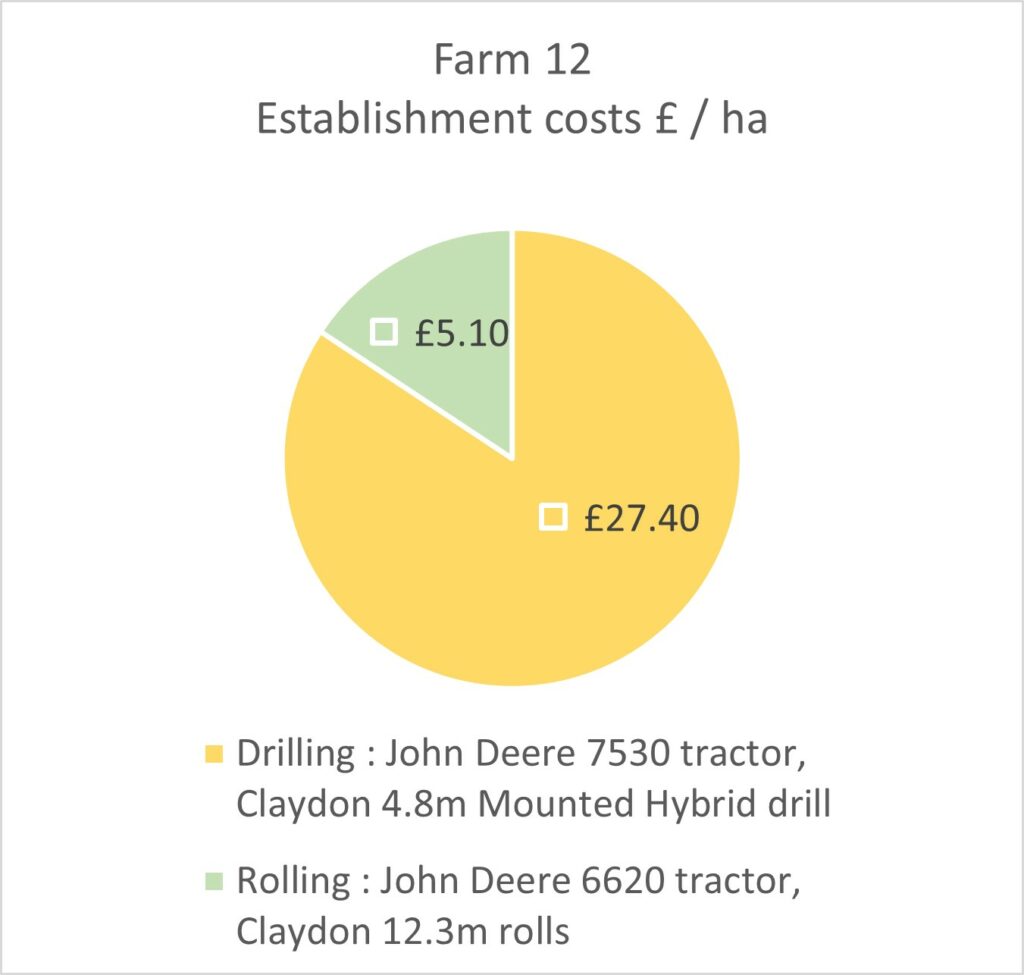

Farm 12 recorded the lowest establishment costs, totalling £32.50/ha for its drilling and rolling operations. The breakdown of costs and machinery used is detailed in the below chart:

It might be expected that the farm with the lowest costs would also have the lowest yields. However, in this scenario, Farm 12 achieved the second highest yields across the 20 AHDB monitor farms at 10t/ha.

The full findings can be found in the following AHDB webinar: www.youtube.com/watch?v=o6QOh030BlQ

Experiences from the field

The experience of those who have converted to the Claydon system supports these findings; far from yield reductions, yields have been maintained at the same level and, in many cases, have increased, as reported by growers across the country:

1) “After just two years of using the Claydon System yields were back to 4.3t/a, while establishment costs were a fraction of what they had been before.” Customer, County Durham.

2) “Since introducing the Claydon System, our average yields have definitely increased. Most of the winter wheats are milling varieties, which average over 9.88t/ha, and we have had up to 12.35t/ha. Oilseed rape has always averaged around 5t/ha – the Claydon System has transformed the way that I farm and helped to ensure the financial sustainability of the operation.” Customer, Lincolnshire.

3) “The objectives were to save time, effort and cost while maintaining yields, all of which have been achieved.” Agronomist, Gloucestershire.

4) “It’s hard to tell whether our yields have increased since moving to the Claydon System, as every year the weather has been the limiting factor. However, we are certain that yields haven’t declined, while our costs have reduced dramatically.” Customer, West Sussex

Claydon two-tine technology helps increase yields

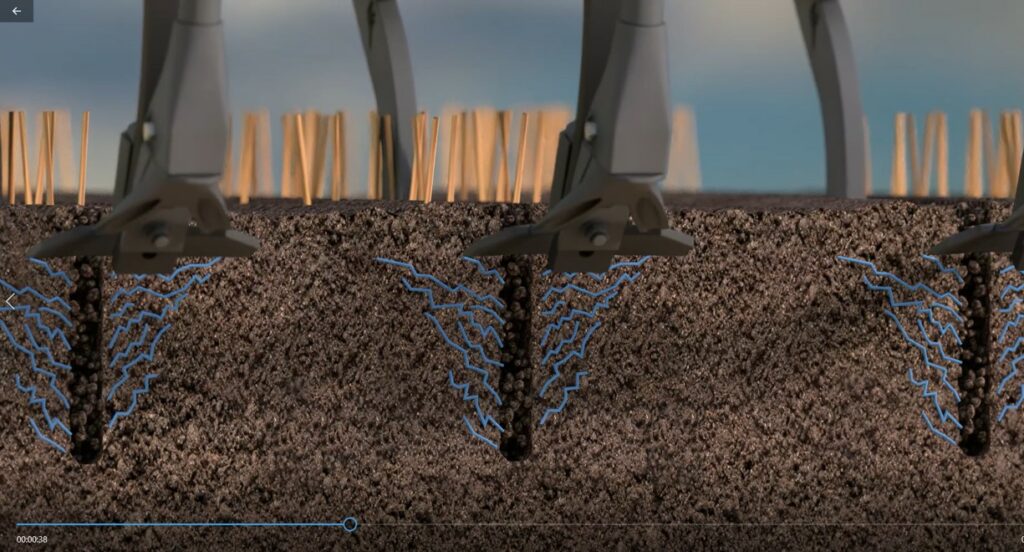

The Claydon drill seeds direct into stubble, with the leading tine loosening and aerating soil in the rooting and seeding zone, giving the seed the perfect environment to grow away quickly and with ease, Claydon says.

Water drains away from the seed which is placed in a band of tilth above. The seed taps into moisture conserved in the undisturbed banks of soil either side of the seeded band. Air and light infiltrate the seeded rows.

Worm populations thrive in the undisturbed soil, and nutrient levels increase. A healthy environment is therefore provided for the growing crop, reflected in healthy yields, Claydon claims.

To read about the experiences of other customers in your area, who are not only reducing their costs but experiencing healthy yields, visit https://claydondrill.com/our-customers/

To discuss how to reduce your establishment costs without yield penalties, call your local Claydon dealer or call Claydon direct on on 01440 820327.