Efficient & lightweight – Solitair DT from LEMKEN

30th January 2023

Incredibly easy to tow, integrated compact disc harrow, comfortable operation and a large, optionally divided seed hopper – that is LEMKEN’s new Solitair DT seed drill, available in working widths

Incredibly easy to tow, integrated compact disc harrow, comfortable operation and a large, optionally divided seed hopper – that is LEMKEN’s new Solitair DT seed drill, available in working widths of 4 and 6 metres.

Greatest possible efficiency with maximum precision – these were the maxims set for designing the Solitair DT. The result is a drill combination with truly impressive performance: lighter and more efficient.

Preparation is everything

Reliable levelling – The wheelmark eradicator tools remove the tractor wheelmarks. The optional leading tyre packer additionally produces crumbled soil ahead of the disc section. The tyre packer can be replaced by a levelling tine section to level the ground evenly.

(Image – Tractor wheel mark eradicators)

Optimal seedbed preparation

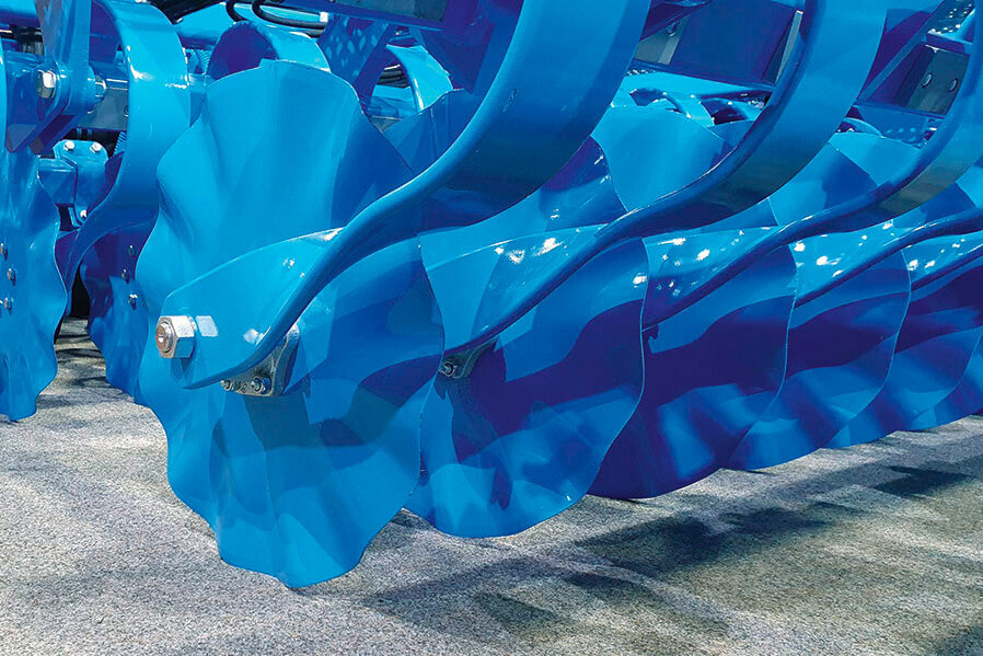

The integrated Heliodor compact disc harrow leaves an evenly loosened, finely crumbly, level seedbed. Corrugated discs are optionally available for less intensive seedbed preparation.

For precise depth control each disc is individually attached to the frame via leaf springs for precise depth control. Unlike commonly used rubber buffers, leaf springs guarantee that the discs have significantly higher track stability during operation. Optionally, these are also available with hydraulic adjustment.

Low disturbance wavy Disc

For less intensive soil mixing, the 22-mm corrugated discs have a waveform shape. These discs are particularly suitable where the germination of weeds is to be suppressed. In dry regions, corrugated discs allow water- saving seedbed preparation because only the area in front of the seeding coulters is loosened. The use of corrugated discs reduces tractive force requirements even further.

he high-quality axial angular ball bearings ensure lasting, flawless function of the discs. The bearings are completely encapsulated so that no dirt can penetrate.

(Wavy disc for low disturbance seeding)

A better start for your crops

Precise fertiliser placement – The fertiliser coulter bar can be attached in front of the tyre packer roller As an option. Fertiliser is precisely placed at the desired depth between two rows of seeds with up to 150 kg share pressure via the double disc coulters.

The Solitair DT can be used for seeding with fertilisation or for sowing different seeds. The two variants single-shot and double-shot version are available.

Optimal reconsolidation

The tyre packer roller not only serves a transport function but also ensures that the entire seedbed is reconsolidated evenly. The generously dimensioned tyre packer roller with a 90-cm diameter ensures even reconsolidation across the full seedbed. The staggered arrangement of the individual wheels additionally leads to better self-cleaning and ensures good sowing, even in wet conditions.

(Image – Central full width tyre packer – Staggered for wet weather seeding)

With an additional harrow between the tyre packer roller and the seeding coulters, the seedbed can be optimally levelled. As an alternative to a harrow, a trapeze packer roller (420 mm diameter) can be added to the Solitair DT to obtain a defined pre-consolidation of rows directly in front of the OptiDisc double disc coulters. The roller improves both the smooth operation of the seeding coulters and the soil contact of seeds.

Precise seeding

The maintenance-free parallelogram guided double disc coulter with trailing depth control roller in the OptiDisc coulter bar guarantees precise seed placement and even coverage height. This creates optimal conditions for even field emergence – even at high forward speeds.

The Solitair DT is equipped with the maintenance-free OptiDisc coulter bar. This bar boasts parallelogram-controlled double disc coulters and trailing depth control rollers.

Seeds are pressed into the soil by the depth control roller to ensure even, rapid field emergence. Both coulter pressure and seed depth can be adjusted independently of each other. This ensures that seeds are always placed at the same depth, even at high forward speeds and in changing soils.

The coulter system is available in a hydraulic version (up to 70 kg coulter pressure) and a mechanical version (up to 45 kg coulter pressure). The row spacing is optionally 12.5 cm or 16.7 cm.

(Image – Optidisc coulterbar with optional pre running trapeze packer roller)

Four distribution heads positioned directly above the coulter bar ensure superior transverse distribution.

An integrated hydraulic tramline mechanism is optionally available for the OptiDisc (image 2: distributor with switches tramlines). The symmetrical distribution of the seed tubes in tramline mode ensures that no seeds need to be returned. The seed rate is automatically reduced when the tramline is switched. The easy exchange of the distributor cartridges enables quick adaptation to a wide variety of tramline systems. This increases flexibility – especially when working across farms.

Convenient filling

Whether straight from a big bag or from a front loader bucket – filling the Solitair DT is as straightforward as it gets. Never lose even a single grain or granule again!

The Solitair DT offers, among other things, individually electrically driven and fertilizer-proof metering units and the tool-free change of seed wheel sets. The machine has one metering system per distributor

This allows width section control even in the basic version. Automatic width section control is optionally available.

Very good ergonomic access

Whether for calibration testing, adjustment, or cleaning – the corrosion-resistant metering system is easily accessible. Metering is 100% fertiliser compatible. The tool-free seed wheel change allows a fast switching between different seeds. The speed signal for metering can be from either a radar sensor on the drawbar or the speed signal of the tractor.

(Image – Good access to change seeding wheels and calibration)

iQblue – the digital world of LEMKEN

iQblue’s digital solutions make your field work more efficient and speed up your office work. This leaves you more time for everything you really enjoy. iQ drill is the ISOBUS-based control concept for the Solitair DT. Thanks to the uniform LEMKEN design, drivers quickly find their way around.

Always a good drive!

A giant in the field, safe and agile on the road. The tyres of the Solitair DT run without hydraulic counterpressure and therefore ensure stable handling in all road conditions and at speeds of up to 40 km/h.

To find out more visit https://lemken.com/en-en/agricultural-machines/sowing/seed-drills/seeding-combinations/solitair-dt or contact you local Dealer today!